Are your tiles suddenly cracking and make a popping sound? This could be why

By Fidelis Sakwa

Rampant cases of building collapse in the country not only point to poor workmanship and a wanting oversight on regulations, but are also symptomatic of the use of substandard building materials. A popular trend in adding finishes to a building, is the fixing of tiles on the floor and walls to create a sleek appearance with a high aesthetic appeal. According to a study titled “Production and consumption of ceramic tiles”, the demand for ceramic tiles grew by 2.5% and its production increased by 1.7% in 2020 globally whilst data by Allied Market Research projects that the tile grout and tile adhesives market will grow at a compounded Annual Rate (CAGR) of 2.6% globally for the next four years.

However, we have all experienced tiles in a kitchen, living room, office, shopping mall, supermarket to mention but a few, becoming uneven, lifting, popping up, cracking or falling. In some cases, you will notice a particular area in a building having different tiles from the ones originally used significantly compromising the aesthetics. While this is not by design, itis an indication that the owners of those buildings were forced to incur the costs of replacing some tiles and probably could not find the exact type that was initially used during construction.

The use of cement in tiling works

Falling, cracking and popping of tiles is a very common defect in tile works. It occurs when a tile lifts from its originally installed position and starts pushing other tiles against one another, to create a ‘tent-like’ bump on the floor. The main reason for this is the loss of the adhesive bond between the tile and floor typically resulting from the use of conventional cement paste which has for many years been the preferred method for placing and fixing tiles. As the saying goes, everything has a good side and a bad side. Cement is no different. While cement is widely available and forms a paste that is good in terms of compressive strength, it is much weaker when it comes to tensile strength.

Most tilers and ‘fundis’ note that the tiles laying process can be quite tedious and a serious workload. This is because they always have to pay attention to the quality of cement, thickness and the consistency of paste which are difficult to control. When making the paste, it is critical to apply the right mixing ratios to ensure a robust, long-lasting, and durable mix. Any wrong ratio, poor quality of cement or unevenly stirred mixture will affect the of the performance of the tiling works.

Besides that, the inherent problem with cement paste is that it dries really fast, limiting the chances of adjustment while laying tiles. After drying, the cement paste also tends to shrink; leaving hollow spaces and air bubbles under the tiles. These are the weaker areas that can initially be detected by a hollow sound when walking before it advances into de-bonding, popping and cracking. The rigid nature of the paste adds stress on the tile while the daily hot and cold cycles are likely to cause the mortar and the base layer to detach, resulting in cracked tiles. Additionally, placing any heavy loads on fixed tiles that have hollow spaces, exerts pressure which in a short while leads to de-bonding and cracking due to the brittle nature of tiles.

What can be done?

According to the industry experts, the most appropriate solution, is the use of purpose made tile adhesives which are premixed mixtures of well-selected regular cement, fine graded sand, and chemical additives that significantly increase the bonding strength for placing tiles.

Innovations in the construction industry are progressing rapidly, and the industry now has a tremendous amount of resources to advance construction technology. Many developers now increasingly prefer ready-made products, as the demand for housing grows globally and the adoption of new building technologies fast-tracks supply of more buildings at an upward growth trajectory.

Each type of tile adhesive is designed for a certain performance dependent on the type of surface application, ambient temperature, working mode, size, type and absorption characteristics of the tile in use. The performance requirements are rigidly specified in existing standards in order to provide the best results for users in specific places and environments. Tile adhesives can also be applied to a variety of tiles, stones and surfaces. They are ready-to-blend, available in a great price range, and have exceptional adhesion capabilities. Shrinkage, fractures, and sliding of tiles are all prevented by their superior bonding strength.

The product has improved bond strength and extended coverage when compared to cement paste. They are easy to prepare and apply and the product minimizes mistakes and wastage of the material. Only a pre-determined amounts of water is as indicated by the manufacturer on the pack is mixed with the pack contents to have a ready to use product. Specific tile adhesives can also be used to install tiles over existing tiles where levels allow, eliminating the hassle and the extra charges of having to remove and cart away old tiles during renovation.

Type and quantity of tile adhesive

Despite the seeming simplicity of use, the best results are not a guarantee because of mistakes that might occur. One of the common mistakes tilers make is using the wrong type and quantity of tile adhesive. Tile adhesives are manufactured for fixing specific materials, a stone tile adhesive is unlikely to work on a ceramic or porcelain tile of large dimensions. The wrong choice of adhesives lowers the durability and convenience of the tiles. Surfaces also speak volumes when picking out adhesives. Water-resistant tile adhesives should be picked for submerged areas like swimming pools or surfaces that constantly come in contact with water such as bathrooms or kitchen sinks,. Where a tiler intends to do wall tiles starting from the top, they should look for tiles with a limited slip property. The location should also inform the choice, tiles installed outside and in public spaces will need adhesives with stronger bonding capacity as well as thermal and water-resistant properties to withstand weather variations and pressure exerted by people and heavy loads.

While installing, the tiles should be in good shape and free from loose dirt like dust. In addition, the floors and walls should be leveled, cleaned, and pre-wetted before the tiling starts. When preparing the paste, other than water levels instructed by the manufacturer, the addition of foreign material in the mixture is discouraged so as to maintain the bonding and water resistance properties of the resulting mixture, but most importantly manufacturer’s instructions should be followed to the letter. Do not mix a tile adhesive with a cement product to avoid compromising the attributes of the tile adhesive.

To save on costs, the use of notched trowels is recommended which significantly reduces the adhesive amount by almost 50% as compared to a uniform application with conventional trowels. The use of notched trowels further prevents the formation of large entrapped airspaces between adhesive and placed tile that leads to debonding.

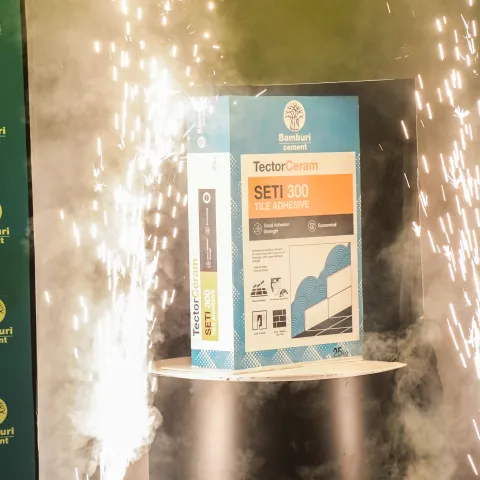

The above-named considerations not only help end up with aesthetically, noise free loose floors but also help the construction industry edge closer to achieving commendable professionalism. This challenges manufacturers in the sector to advance technologies tailor made to suit consumers' needs and concurrently call on consumers to use the latest range of fit for purpose products to achieve top-notch results in their building projects. For instance, Bamburi Cement, through its parent Holcim's Research Centre, recently launched a ready-mix tile adhesive product called Bamburi Tectorceram SETI 300 to address the aforementioned tiling challenges that most developers experience.

A cement paste or sand-cement combination is an old technique for installing tiles and facing or floor stones. Challenges experienced by homeowners and developers are gradually shifting to take advantage of tile adhesives to prevent any future issues like tile-breaking, water-leaking, and debonding from the substrate. The preparation process is also much quicker. The right choice for the protection of your flooring and walls over a long time without having to incur expensive maintenance costs is the use of tile adhesive.

Fidelis Sakwa is the Innovation & Technical Services Manager at Bamburi Cement